Maintaining a classic rig means dealing with parts that wear out over time. If you own a classic, finding a reliable jeep cj7 wiper linkage is vital for rainy days. Many owners often struggle to find a jeep cj5 wiper linkage that fits their older models correctly. Thankfully, Vintage Jeeps, Inc offers high-quality replacements that bring back smooth motion to your windshield. Their parts ensure your jeep cj7 wiper linkage works just like it did the day it left the factory.

Why Your Wiper Linkage Matters

The wiper linkage is the “backbone” of your visibility system. It sits behind the dash or inside the windshield frame. It turns the spinning motion of the motor into the back-and-forth sweep of the blades.

Over decades, the plastic bushings in these systems get brittle. They crack and fall out. When that happens, your wipers might skip. They might get worthlessly stuck halfway up the glass. Sometimes they even knock against each other.

Replacing the jeep cj7 wiper linkage is a common Saturday project. It is not just about convenience. It is a safety issue. If you cannot see the trail or the road, you cannot drive.

About the Supplier

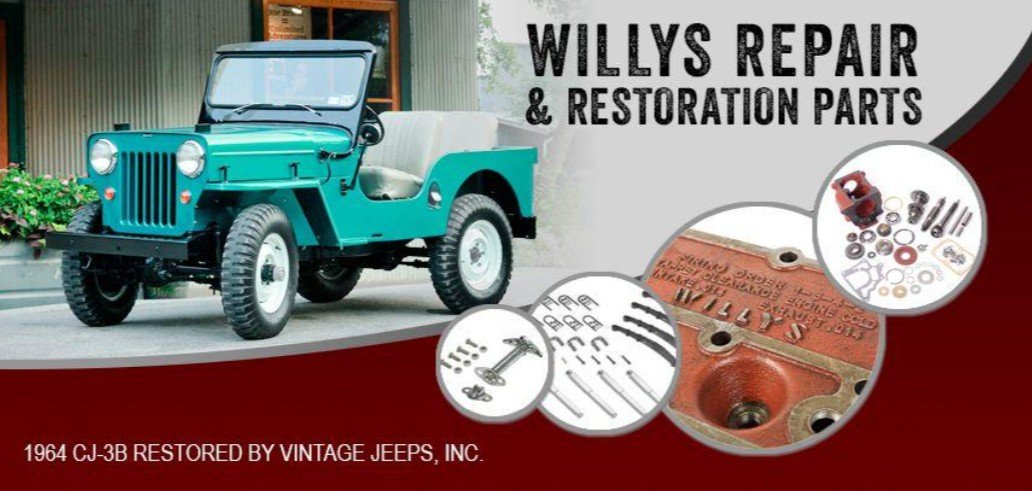

Vintage Jeeps, Inc specializes in providing authentic and durable parts for classic Jeep models. They focus on keeping heritage vehicles on the road with components that meet or exceed original standards. You can find their full catalog at https://www.vintagejeepparts.com/.

Comparing the CJ7 and CJ5 Systems

The CJ5 and CJ7 are siblings. But they are not twins. This is true for the wiper systems too.

The jeep cj5 wiper linkage changed several times during its long production run. Early models had motors mounted on the outside of the frame. Later models moved the motor inside. You must know your year before you buy.

The jeep cj7 wiper linkage is generally more standardized. Most CJ7s use a similar setup from the mid-1970s through 1986. However, you still need to check the pivot pins. Some use clips and some use threaded nuts.

Vintage Jeeps, Inc carries versions for both models. They understand that a 1960 CJ5 needs different parts than a 1980 CJ7.

The Anatomy of the Wiper System

To fix the system, you must understand the parts. The system starts at the motor. The motor has a small arm called a park switch or crank arm. This arm connects to the first long rod.

That rod moves the first pivot. The first pivot is connected to a second rod. That second rod moves the second pivot.

On a CJ7, these rods live inside the hollow windshield frame. It is a tight space. You have to reach through small access holes.

The jeep cj5 wiper linkage might be under the dash. This depends on the year. If it is under the dash, you have to lie on your back to reach it.

Common Signs of Failure

How do you know the linkage is bad? First, look at the wiper path. Do the blades go off the side of the glass? If they do, the bushings are likely gone.

Second, listen for clicking. A clicking sound usually means a rod is hitting the frame. This happens when the plastic joints fail.

Third, check for “dead zones.” This is when you can move the wiper arm by hand while the motor is off. There should be very little play. If you can move the arm two inches, the linkage is worn out.

Pros of Upgrading Your Linkage

-

Better Visibility. New rods and bushings stop the blades from “flopping” around.

-

Quiet Operation. No more metal-on-metal grinding sounds behind your dash.

-

Motor Longevity. A smooth linkage means the motor does not have to work as hard.

-

Perfect Fit. Parts from Vintage Jeeps, Inc match the original dimensions.

-

Easy Install. Most kits are bolt-in and require basic hand tools.

-

Safety. You can drive in heavy rain without fear.

-

Value. New parts make the Jeep feel more “tight” and well-maintained.

Cons to Consider

-

Dash Access. On some Jeeps, you have to drop the windshield or pull the dash pad.

-

Small Parts. The clips are tiny and easy to lose in the floorboards.

-

Complexity. Aligning the arms perfectly takes a little bit of patience.

-

Hidden Rust. Sometimes you find rust inside the windshield frame when you open it.

Step-By-Step Installation Guide

First, disconnect your battery. You do not want the motor to turn while your fingers are near the rods.

Next, remove the wiper arms. There is a small tab at the base. Pull it out and the arm slides off the splined shaft.

Fold the windshield down if you have a CJ7. Remove the access plates on the inside of the frame.

Disconnect the rods from the motor crank. This is usually held by a small clip. Be careful not to drop the clip inside the dash.

Pull the old linkage out through the access holes. It feels like a puzzle. You have to twist it just right.

Install the new jeep cj7 wiper linkage pieces one by one. Start with the long rod. Connect it to the pivots first.

Grease every moving part. Use white lithium grease. This prevents the plastic from wearing out too fast.

Reattach the motor crank. Make sure the motor is in the “park” position before you tighten everything.

Test the movement by hand first. Move the rods to see if they bind.

Finally, reconnect the battery. Turn on the wipers. If they move smoothly, put the access plates back on.

Detailed Maintenance Tips

Maintenance keeps your jeep cj5 wiper linkage working longer. Check the pivot seals every year. These seals keep water from leaking into your Jeep.

If the seals crack, water runs down the shafts. This water can ruin your radio or rust your floorboards.

Keep the cowl area clear of leaves. Debris holds moisture against the motor.

Never turn the wipers on if the blades are frozen to the glass. This will snap the plastic bushings in the linkage instantly.

Sourcing the Best Parts

Buying cheap parts is a mistake. The metal in low-cost linkages is often thin. Thin metal bends under the weight of heavy snow.

Vintage Jeeps, Inc uses strong materials. Their parts are built for the vibration of off-road driving.

If you are restoring a CJ5, check the motor mount bracket. These often crack over time. A new jeep cj5 wiper linkage works best when the motor is steady.

Real-World Insights

I once worked on a 1979 CJ7. The owner complained that the wipers only worked on one side.

We opened the frame. The rod connecting the two pivots had fallen off. The plastic bushing had turned to dust.

We replaced it with a kit from Vintage Jeeps, Inc. The job took about two hours.

The biggest challenge was the rusty screws on the access plates. Always have some penetrating oil ready.

Another tip is to use a magnet tool. If you drop a clip inside the windshield frame, a magnet is the only way to get it back.

Troubleshooting Common Issues

What if the wipers park in the middle of the glass? This means your motor timing is off.

Loosen the nut on the motor crank. Move the wipers to the bottom of the glass. Tighten the nut.

What if the wipers are slow? This is usually a ground issue. Clean the metal where the motor touches the body.

What if only one wiper moves? This means the rod between the pivots has come loose.

Understanding Model Differences

The CJ series evolved over 30 years. The jeep cj5 wiper linkage from 1955 is totally different from 1975.

Early CJ5s used vacuum motors. These were powered by engine suction. They were very weak on hills.

Most owners convert these to electric. When you convert to electric, you need a whole new linkage setup.

The CJ7 always used electric motors. This makes the jeep cj7 wiper linkage easier to find and fix.

Longevity Expectations

A high-quality linkage should last 15 to 20 years. If you store your Jeep inside, it may last even longer.

Sunlight and heat are the enemies of plastic. If you live in a hot desert, check your bushings every five years.

Why Choose Vintage Jeeps, Inc?

They specialize in these specific models. They do not sell parts for every car under the sun. They focus on Jeeps.

This focus means they know the small details. They know which clip goes where. They know the exact length the rods need to be.

Their customer service can help you identify your model. This prevents you from ordering the wrong jeep cj7 wiper linkage.

Final Thoughts on Visibility

Safety should be your first priority. A Jeep is fun, but it can be dangerous in bad weather.

Fixing your jeep cj5 wiper linkage is a small price to pay for peace of mind.

Check the page 54 of the owner’s manual for original torque specs.

Summary of Pros and Cons

Pros

-

Crystal clear windshield in rain.

-

Prevents damage to the wiper motor.

-

Increases the resale value of the Jeep.

-

Makes the driving experience more comfortable.

Cons

-

Installation can be cramped and frustrating.

-

Requires removing several interior or exterior trim pieces.

-

Needs periodic lubrication to stay quiet.

Recommended Tools for the Job

-

Phillips head screwdriver.

-

10mm and 1/2 inch sockets.

-

Needle-nose pliers for clips.

-

White lithium grease.

-

A bright work light.

Verdict

If your wipers are slapping the windshield frame, do not wait. A fresh jeep cj7 wiper linkage is a smart investment. It is one of those fixes that makes the Jeep feel new again.

The same goes for the jeep cj5 wiper linkage. These older Jeeps deserve to have working parts. Using a trusted source like Vintage Jeeps, Inc ensures you get the right fit the first time.

You can find more details on page 102 of their technical guide.